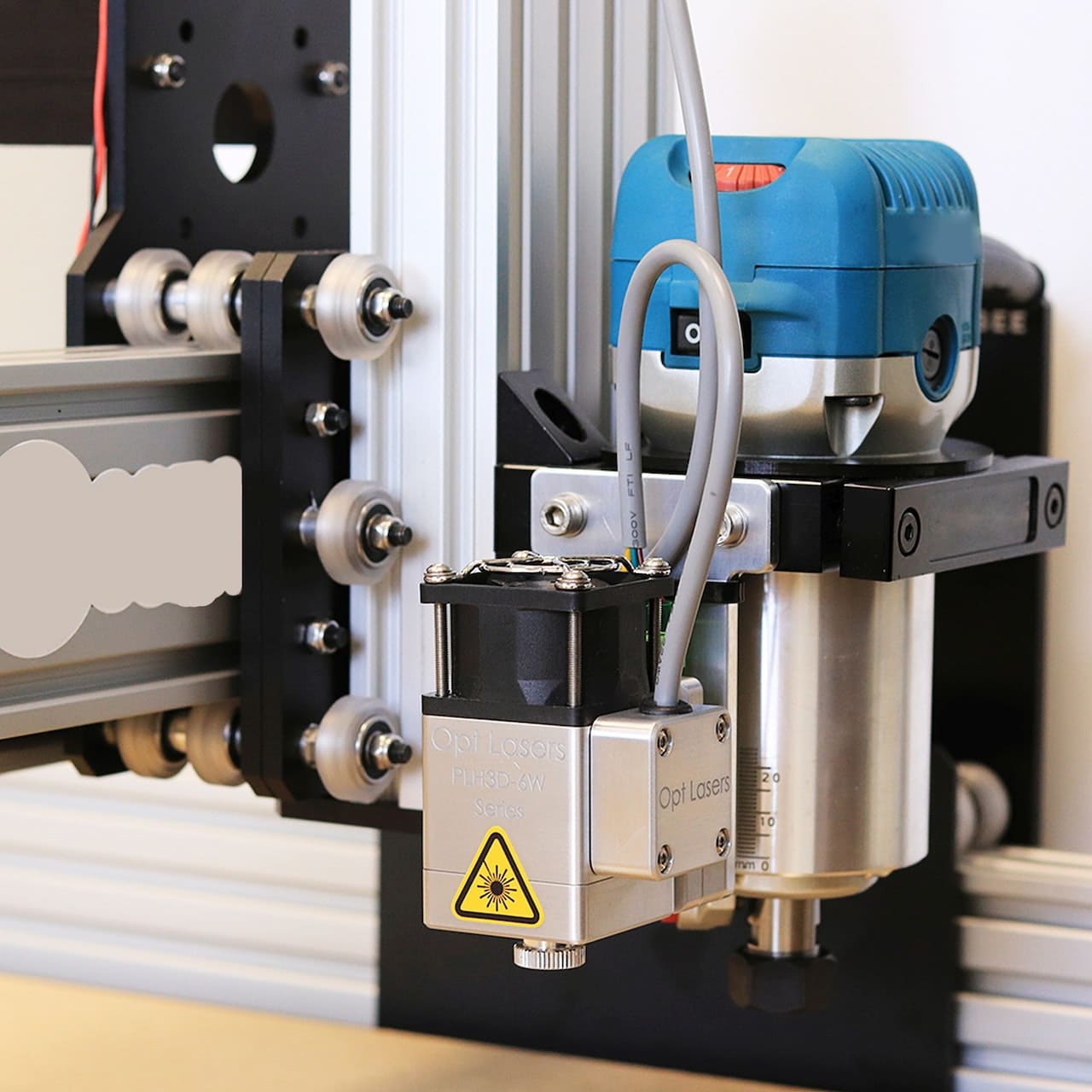

Laser Fabric Cutter

With the world of fashion and textiles continually changing, cutting fabric requires more technology-driven processes to keep up with trends. The innovation of fabric laser cutter has revolutionized how materials can be processed within efficient time frames yet still give an exquisite finish. But just how have these fabrication lasers been helping for the better? As we explore this new technology further, it’s clear that its efficacy has quickly become an industry standard that shows no signs of slowing down its advantages any time soon.

Here Are Seven Ways How Innovation Of Laser Fabric Cutter Helped For The Better:

1. Increased precision in cutting fabrics

As the fashion industry grows and evolves, so do the technologies that support it. One such innovation is the laser fabric cutter, revolutionizing how fabrics are cut. Unlike traditional cutting methods, which rely on shears or rotary blades, laser fabric cutters use focused beams of light to cut through materials with extreme precision.

This technology facilitates faster production times, minimizes waste, and maximizes accuracy. As a result, designers can experiment more with fabric designs and create complex shapes and patterns without sacrificing quality. Ultimately, the laser fabric cutter helps the fashion industry produce higher-quality products faster and more efficiently, benefiting designers and consumers.

2. Reduced time required for cutting fabrics

In the world of fashion and textiles, every second counts. With deadlines looming and production timelines getting shorter, every innovation that can speed up the manufacturing process is a welcome development. The laser fabric cutter is one such innovation that has revolutionized the way fabrics are cut.

Gone are the days when material had to be cut manually or with the help of a machine. With laser technology, fabrics can be cut precisely and accurately, reducing production time by a significant margin. Not only does this save time and money, but it also reduces waste because fabrics are cut with unparalleled precision. The laser fabric cutter is indeed a game-changer in the industry, helping to improve productivity and efficiency to a whole new level.

3. Improved automation in fabric cutting process

The innovation of laser fabric cutters has significantly improved the fabric-cutting process, making it more efficient and precise. So, you must know why a fabric laser cutter is the best solution. Traditional cutting methods, such as scissors or rotary cutters, often result in discrepancies in fabric sizing, but those discrepancies are significantly reduced with the precision of laser cutters.

Beyond accuracy, laser-cutting technology reduces fabric waste and increases the speed of the manufacturing process, leading to lower production costs and faster turnaround times. With all these benefits in mind, it’s no wonder that the arrival of laser fabric cutters has been celebrated throughout the fashion and textile industries.

4. Increased efficiency in fabric cutting

The innovation of laser fabric cutting has revolutionized the textile industry and has contributed significantly to increased efficiency in fabric cutting. Gone are the days when tedious manual labor was required to cut fabric, which was time-consuming and often resulted in wastage due to inaccuracies.

Laser fabric cutting has significantly reduced the time and effort needed to cut fabric, providing precision and accuracy. This technological advancement has not only improved productivity but has also helped minimize waste, making it an environmentally-friendly option. The laser fabric cutter is one technology that has truly helped the industry for the better, and it is exciting to see the potential further innovations in technology will bring.

5. Enhanced consistency in fabric cutting

The innovation of laser fabric cutters has revolutionized the world of fabrics and textiles. Gone are the days of uneven and imprecise cuts that compromised the quality of the final product. With enhanced consistency in fabric cutting, creating beautiful and professional-looking garments is easier than ever. The precision of laser cutting allows for quicker production times, reduced waste, and increased efficiency in the industry.

These benefits go beyond just production – laser cutting also allows for greater creativity and accuracy in design, opening up new possibilities for fashion and textiles. All in all, the innovation of laser fabric cutters has been a game-changer for the industry, helping to create better, more consistent, and more sustainable products.

6. Reduced fabric waste during the cutting process

Innovation constantly changes how we do things, and the laser fabric cutter is no exception. This incredible technology has revolutionized the way fabric is cut and has positively impacted the environment. One of the most significant advantages of the laser fabric cutter is reducing waste during the cutting process.

Using a laser, the machine ensures that the fabric is cut precisely to the required shape every single time, thus, eliminating any unnecessary scrap. The result is a cutting process that generates less textile waste, which is sustainable and good for the bottom line. The laser fabric cutter proves that innovation can make a difference in our daily lives and the world.

Sewing

7. Improved speed and accuracy in the production of garments

The fashion industry has long been searching for ways to improve the speed and accuracy of garment production. Enter the innovative laser fabric cutter, a game-changing technology revolutionizing how clothes are made. But you must know the advantages and disadvantages of laser technology. Unlike traditional fabric cutters that require manual labor and are time-consuming, laser fabric cutters utilize computer-controlled precision to create sleek, clean cuts, increasing production efficiency.

Furthermore, this innovative tool promotes sustainability by dramatically reducing fabric waste and minimizing the risk of error. As such, the adoption of laser fabric cutters heralds a bright future for the fashion industry, promising faster, more sustainable, and more precise production of garments.

Conclusion

To conclude, implementing laser fabric cutters has revolutionized the fashion industry. From helping small businesses save time and money to modernizing output in large companies, this innovation is more efficient than ever before. It is also reducing unnecessary waste by creating precise lines and accurate designs without scrap fabric to dispose of afterward. With improved accuracy comes reduced risk-taking within businesses that now have a safety net allowing them to take new risks confidently. All these advances benefit everyone included in the production and wear of couture garments. Laser fabric cutting enables garments to be made with much less effort while maintaining high-quality quality.