Cable

Cable testing is a process that measures the electrical properties of cables to understand how cables should be operated. The property being measured is usually one-turn tension and is usually measured per unit length of cable.

The benefits of performing cable testing range from providing greater reliability during construction projects to increased the service life of cables and reducing downtime caused by failures in the field. In general, cable testing can provide greater benefits than traditional methods such as direct measurements or calculations with inadequate assumptions. For top-notch cable testing, you can check out HV Diagnostics.

Who Benefits From Cable Testing

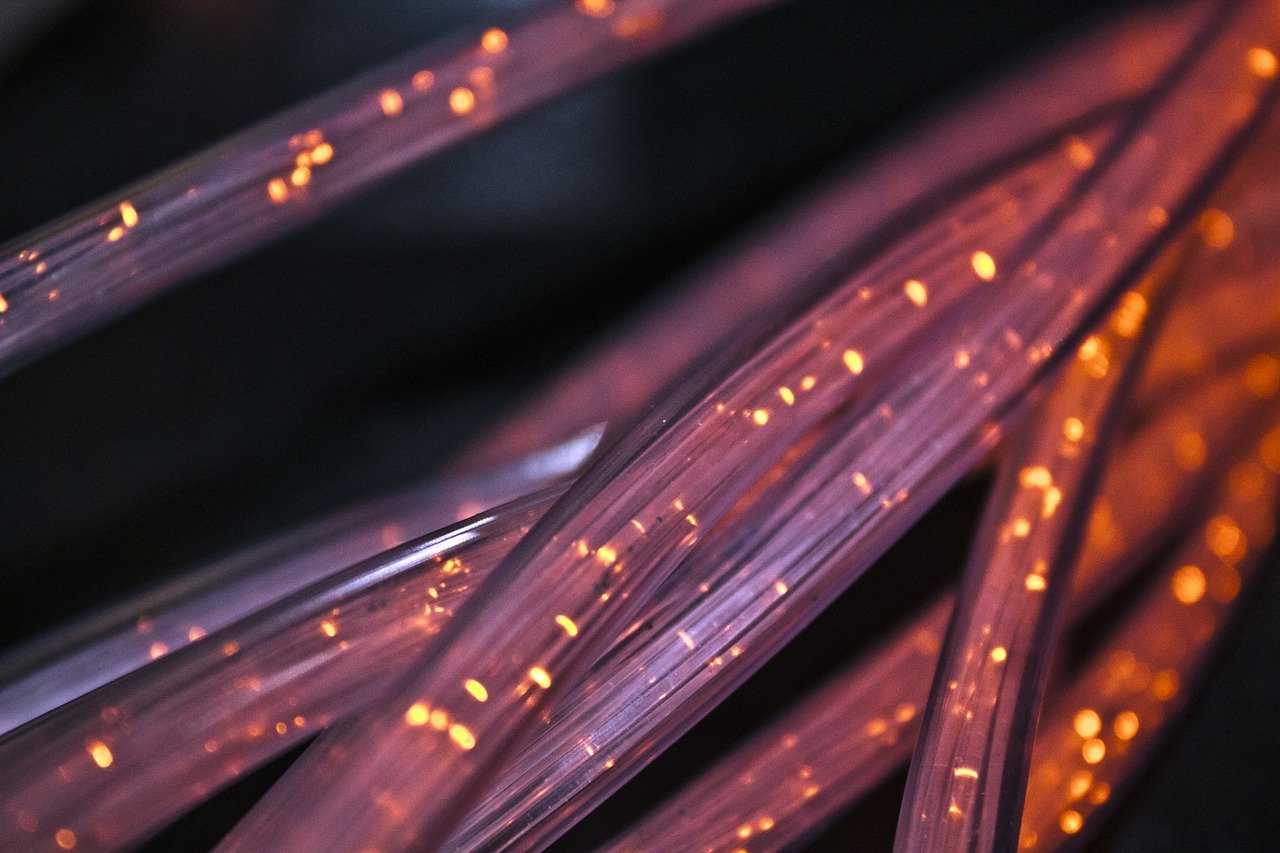

Organizations that need to test optical cables include providers of fiber optic infrastructure, data transport equipment manufacturers, installers who are installing pipes or trunks, network operators who need to verify that their networks are operating correctly and ensure their customers can receive high-quality connections using optical fibers.

For Maintenance Purposes

One of the benefits of cable testing is the ability to prove that the cable was maintained properly while in use through maintenance records. Another benefit, and often a primary reason for performing cable testing, is the ability to measure strain during cables being used at any given time. Cable testing can also provide a means of measuring the amount of voltage drop in cables that can cause life-threatening shorts during construction projects.

Safety

The first and foremost issue of cable testing is to ensure the safety of the users. This can be accomplished through insulation, high voltage, and tightness tests, as well as mechanical tests that are used for determining the strength and durability of our cables.

Cable testing can also provide the ability to safely check voltage drops during construction projects. A cable tester will typically test a single cable or group of cables at one time and back-to-back test groups of cables. This allows for a calculation of the overall voltage drop in the installation.

Cable testers also measure the integrated tension in each measurement along the entire length of each cable, which provides additional information about any differential between stress along different lengths of cable. Information like this can assist in predicting the failure of cables in the field.

Determine Cable Health

Another benefit is the ability to provide a visual representation of a cable’s state of health. Reliable visual representations are a good way to guide decisions about maintenance requirements. Cable testing can commonly detect small changes in electrical properties from a cable that may be caused by corrosion or rodent damage. Electrical properties can also be observed at various temperatures, which is useful for determining the appropriate service—temperature range for cables exposed to certain environmental conditions.

Keeping up to Code

The tests also help ensure that cables can handle the demands of modern technology and sustain their functionality over time, protecting your home and your existing investment. Cable testing protects your power, television, and security systems by ensuring that they are safe and reliable.

Cable testing is an important part of the manufacturing process at all levels, from initial design assistance through to final test results. Most manufacturers use a standard or industry-recognized test for this purpose, but some choose to use in-house methods or commercial solutions for certification.

How is Cable Testing Done?

Cable testing refers to a process of transmitting ongoing electrical signals in order to determine whether a cable or network is reliable. It is typically done through transmitters and receivers that can send pulsed currents on long cables, short cables, networks, or computer-to-computer connections.

The process of combining the audio signal of the channels with the pulses being transmitted allows for a more detailed examination of deep levels within transmission lines.

“Transmission line testing” is common throughout multiple industries, including telecommunications and power distribution.

The process involves sending pulses through a cable or network so that voltage and current signatures can be captured. These signatures reveal which parts of the circuit are working correctly, as well as cables and connectors. It is often required for new installations or extensions to existing cable networks. When an existing work is being renovated, it can help reduce the time needed to complete the project using screening software that identifies potential problems early on. This helps customers avoid costly delays.

Transmission line Testing

Transmission line testing is used to determine an average power draw of a cable and a signal-to-noise ratio (S/N). The process involves sending a series of pulses through a system with an S/N ratio that is selected so that the system provides the proper signal for detecting defects