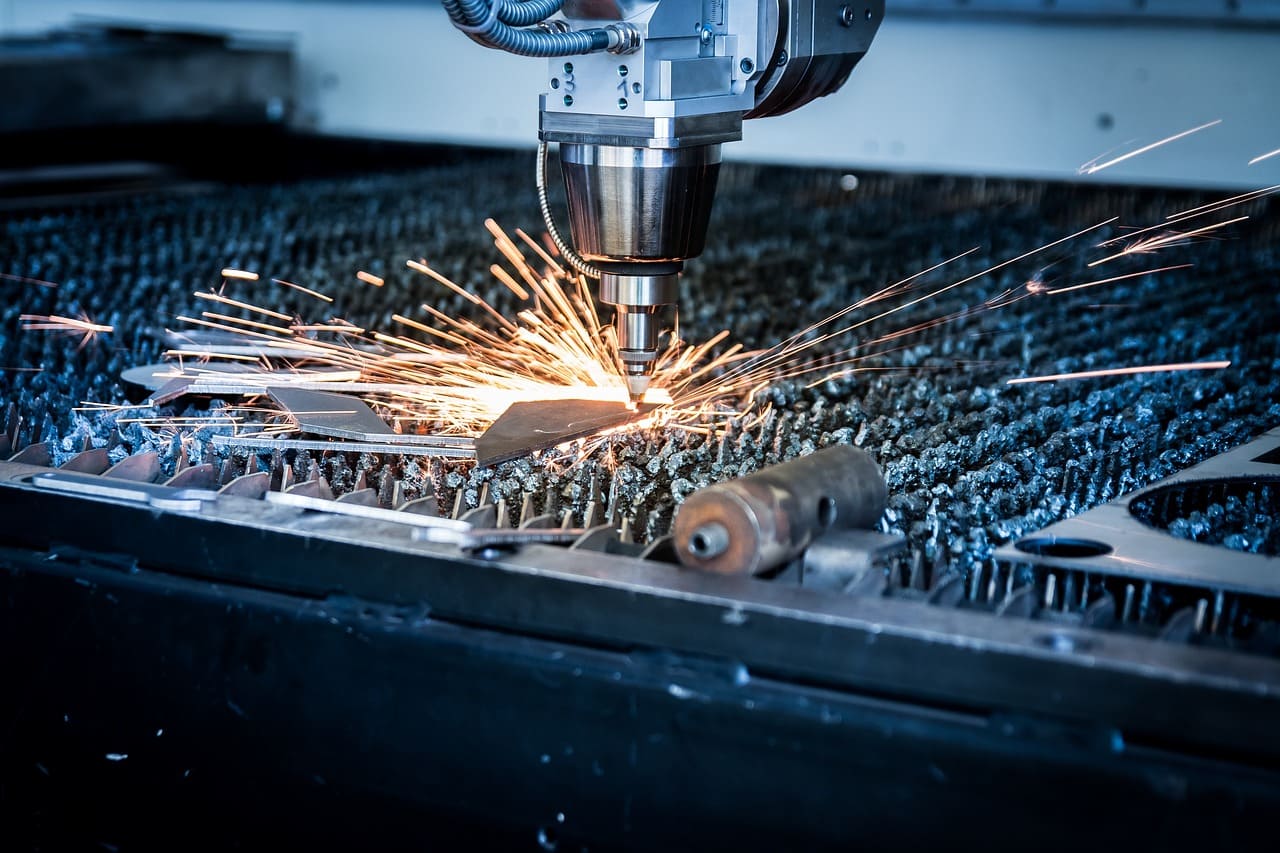

laser cleaning machine

From historical artifacts to modern manufacturing equipment, effective cleaning techniques are vital for preserving materials and ensuring longevity. One cutting-edge method that has gained popularity in recent years is laser cleaning. In this comprehensive guide, we will delve into the benefits of using laser cleaning machines, exploring their versatility and numerous advantages for different applications.

Laser cleaning is a non-contact, non-abrasive process that utilizes high-energy laser beams to remove contaminants, rust, paint, and other unwanted materials from surfaces. This technology offers a powerful and environmentally-friendly solution, making it increasingly popular across various industries.

Unrivaled Precision and Selectivity

One of the most significant benefits of laser cleaning machines is their unparalleled precision and selectivity. With the ability to focus the laser beam on specific areas, users can effectively clean surfaces without causing damage to the surrounding materials. This feature makes laser cleaning ideal for applications that require precision, such as cleaning delicate artifacts or sensitive electronic components.

Minimal Thermal Effects

Another advantage of laser cleaning is the minimal heat generated during the process. Since the laser beam is highly focused, it quickly and efficiently removes contaminants without causing excessive heat buildup. This reduces the risk of thermal damage to the material being cleaned, making it a suitable option for heat-sensitive materials.

Environmentally-Friendly and Safe

Laser cleaning systems offer an eco-friendly alternative to traditional cleaning methods. They eliminate the need for harmful chemicals, abrasive materials, and large quantities of water, reducing the overall environmental impact. Additionally, since laser cleaning is a dry process, it minimizes the production of hazardous waste.

Reduced Health Risks

With the elimination of harmful chemicals, laser cleaning machines significantly decrease health risks associated with traditional cleaning methods. Workers are no longer exposed to toxic substances or airborne particles, resulting in a safer work environment.

Increased Efficiency and Productivity

Laser cleaning machines can drastically improve efficiency and productivity in various applications. Their non-contact nature allows for faster cleaning times compared to manual or abrasive methods. Additionally, the precision and selectivity of laser cleaning reduce the likelihood of rework or damage, further enhancing productivity.

Lower Maintenance and Operational Costs

The non-abrasive nature of laser cleaning machines also contributes to reduced maintenance and operational costs. Traditional cleaning methods often cause wear and tear on equipment, leading to frequent repairs or replacements. In contrast, laser cleaning machines experience minimal wear, resulting in lower long-term costs.

Versatility Across Various Applications

Laser cleaning machines can be utilized in a wide range of industries and applications. From aerospace and automotive to cultural heritage preservation and microelectronics, the benefits of laser cleaning are evident across various sectors. This versatility makes it an attractive option for companies seeking efficient, eco-friendly cleaning solutions.

Customizable Solutions

Laser cleaning machines offer a high level of customization, allowing users to adjust parameters such as laser power, pulse duration, and repetition rate to suit their specific needs. This adaptability ensures optimal cleaning results for various materials and contamination levels.

Enhanced Surface Quality and Preservation

Laser cleaning not only remove contaminants effectively but also improve the surface quality of the treated material. Unlike abrasive methods that can alter the surface texture, laser cleaning maintains the original surface properties. This preservation of surface integrity is particularly valuable for applications where maintaining the material’s original condition is crucial, such as art restoration or semiconductor manufacturing.

No Secondary Contamination

Another advantage of laser cleaning is the elimination of secondary contamination. Traditional cleaning methods often involve the use of chemical solvents or abrasive materials, which can leave residues or cause additional surface damage. In contrast, laser cleaning generates no secondary contamination, ensuring a pristine surface after the process.

Remote Operation and Automation Capabilities

Laser cleaning machines can be operated remotely, reducing the need for direct human interaction with the equipment. This feature is particularly beneficial in hazardous environments or when dealing with toxic materials. Furthermore, laser cleaning systems can be integrated into automated production lines, further streamlining the cleaning process and minimizing human intervention.

Reduced Downtime

The non-contact nature of laser cleaning machines, combined with their remote operation capabilities, results in reduced downtime for maintenance and cleaning. Traditional methods may require the disassembly of equipment, resulting in significant production delays. Laser cleaning, on the other hand, can be performed on-site and often without interrupting ongoing operations, ensuring minimal disruption to production schedules.

Improved Compliance with Regulations

The use of laser cleaning machines can help businesses comply with increasingly stringent environmental and safety regulations. By eliminating the need for hazardous chemicals and reducing waste generation, companies can more easily meet regulatory requirements and demonstrate their commitment to sustainability.

Enhanced Reputation and Marketability

As businesses become more environmentally conscious, adopting eco-friendly cleaning methods like laser cleaning can enhance a company’s reputation and marketability. By investing in laser cleaning technology, companies can showcase their dedication to sustainable practices and attract environmentally conscious customers and partners.

Conclusion

The numerous benefits of laser cleaning machines, ranging from precision and safety to environmental friendliness and versatility, make them a valuable addition to various industries. As technology continues to advance, it is expected that laser cleaning machines will become even more efficient, accessible, and adaptable, further solidifying their position as a preferred cleaning method.

By embracing the power of laser cleaning, businesses can not only improve their operational efficiency and productivity but also contribute to a cleaner, greener future. With its multitude of advantages and potential applications, laser cleaning technology is poised to revolutionize the way we clean and maintain materials, equipment, and artifacts, providing innovative solutions to age-old challenges.