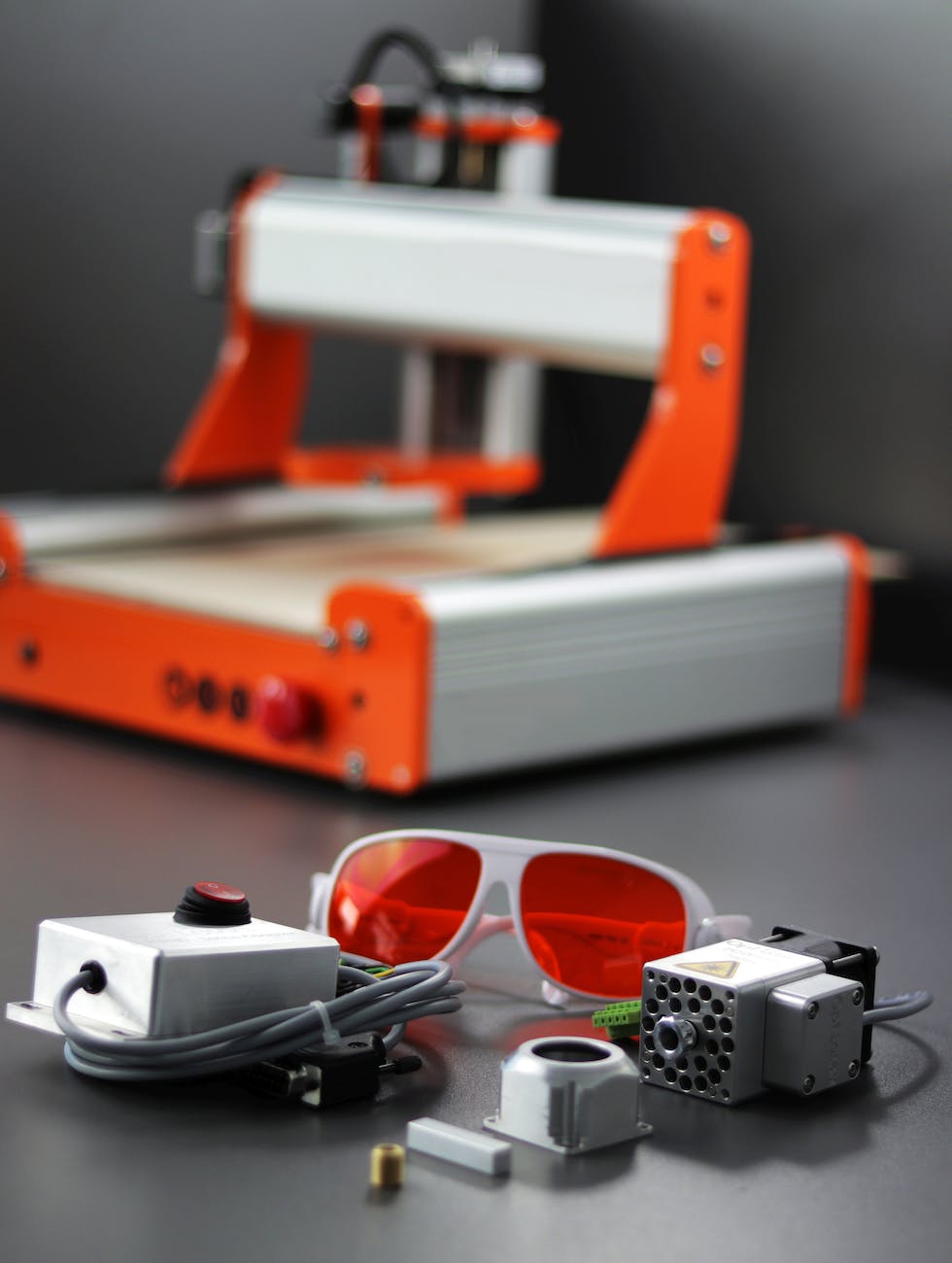

Perfect Laser Engraving Machine

With the help of a focused laser beam, a laser engraving machine can etch or burn text and drawings onto a wide range of materials. I was astounded by the potential of the technology when I received my first laser engraver from GearBerry. So I’ll describe what laser engravers are, how they operate, what you can engrave with them, and the many types in this post.

Ingenious working concept

A laser engraver operates in a fundamentally ingenious yet relatively straightforward manner. The substance you want to engrave is exposed to a powerful laser beam that produces enough heat and energy to burn, melt, vaporize, or otherwise remove it. The engraving you want is made by removing material in accordance with the text, pictures, or pattern you enter into the machine’s software. But the level of accuracy that laser engravers can reach is what makes them so amazing.

High-resolution digital vectorization and graphics technologies that can accurately direct the movement of the laser according to your design are used to manage the laser beam. Resolutions of 1200 dots per inch or greater are possible when the laser beam is moved across the material with micrometer accuracy using mirrors and lenses. The laser engraver can produce exceptionally fine engraving details, sharp edges, and clear text — even at the microscopic level — thanks to this exact beam control and location. The engraving resolution and quality can be further enhanced by using the laser at extraordinarily fast frequencies, ranging from the tens of kilohertz to the megahertz range.

Some prevalent species

The employment of different laser types for engraving is practical. CO2 lasers and fiber lasers are the most often used. My Longer RAY5 also belongs to the CO2 laser. Infrared light emitted by CO2 lasers is well absorbed by a variety of organic materials, including leather, polymers, and wood, making these substrates an excellent choice for engraving. However, they often have a lower resolution.

Particularly for engraving metals and ceramics, fiber lasers offer greater resolutions and engraving rates. They do, however, often cost more than CO2 lasers. Both types of lasers use a set of lenses and movable mirrors that may be digitally adjusted to precisely concentrate the beam onto the material surface.

The design or text pattern that you provide into the machine’s software is followed by the laser beam when engraving. The surface of the material is removed and transformed as a result of the laser’s impact by burning, melting, oxidizing, or rupturing the molecular bonds in the substance. As a result, wood, metal, plastic, or even glass can be precisely etched or engraved as desired.

Definitely not a disappointing try

The variety of materials that GearBerry laser engraver can work with is astounding, ranging from everyday items like wood and acrylic to more unusual choices like glass and metal alloys. Theoretically, almost any substance that can absorb laser energy and undergo physical or chemical changes when heated can be etched with the right settings and laser type. The following are some of the most popular material types that laser engravers excel at:

Wood

Different wood species absorb CO2 laser infrared photons in different ways, creating aesthetically varied effects. Hardwoods with attractive grain emphasized engravings and a naturally textured finish include oak, maple, and walnut.

Metal

It is possible to engrave non-ferrous metals like aluminum and brass as well as ferrous metals like steel to create long-lasting, high-contrast markings. The best engraving of various metal alloys and thicknesses may require special settings and parameters.

Plastics

Through localized melting and vaporization of the material, which produces precise patterns, several types of plastic can be laser etched. Nylon, PVC, Delrin, acrylic, polycarbonate, and other materials are typical choices. Images created with acrylic are frequently among the sharpest.

Glass

Glass can be locally heated and etched using a technique called ablation with both CO2 and fiber lasers. While other glass kinds might need unique optics and settings, soda-lime glass often generates engravings that remain unchanged.

Leather

In a controlled manner, laser energy chars and destroys portions of the leather’s surface, leaving behind fine textures and high-contrast markings with a natural-looking finish. Based on the leather’s thickness and finish, settings change.

Ceramic

Ceramic coatings applied to materials like glass or metal can be successfully marked to create lasting designs even when direct engraving is challenging.

Composites

If the resin matrix in the fiberglass, carbon fiber, and other composite materials can absorb the laser energy without overheating and harming the reinforcing fibers like carbon nanotubes, then these parts can be engraved.

Exotics

When employing the right laser wavelength, power levels, and processing settings, marking can be done on even materials that are very challenging to machine, such as titanium alloys, tungsten, rubber, fake stone, and gemstones.

Conclusion

In general, laser engraving devices are a fantastic technology that offer you practically limitless creative options. Lasers have transformed the art of engraving by generating precise industrial components as well as creatively personalizing leather products and wood gifts.

So if you’re looking for an affordable, high-quality laser engraver for your personal or small business use, I highly recommend checking out the options at GearBerry. Their team of experts helps you find the ideal machine to fit your specific needs and budget. And for a quality, dependable CO2 laser engraver at an affordable price, I would point to the Longer RAY5, which has become my go-to tool for all my creative laser engraving projects.

You should now have a solid understanding of what laser engraving machines are, how they operate, and the several types that are available. Please feel free to ask me any further questions if you have any. Any extra information that could assist you in determining whether laser engraving is the best option for your needs will be gladly provided.