Waterjet’s

Water quality and temperature are key factors in a waterjet’s operating costs, life expectancy, and productivity.

Water jet cutting machine owners can experience decreased life in any pump that comes into direct contact with water. These can include high-pressure seals, plungers, and high-pressure lines.

John Petras is the service manager at a big company. He says that while over 90% of water comes from cities in the U.S. or Canada, it can still be used without conditioning. However, the small percentage that comes from outside the United States and Canada can cause problems for the machine.

“Almost all companies have enough water to run their waterjets without conditioning them,” Petras says that water conditioning is an exception to the rule.

Water is everywhere, but is it possible to use?

Petras says water is a complex subject. We have a range of water specifications that we like for our waterjets. It can’t be either too pure or impure. You’ll have adverse effects on your pump, nozzle, and possibly the material you are cutting, regardless of which waterjet you use.

Petras says that water too pure, such as deionized, can cause it to be very aggressive. It will try to dissolve minerals in the waterjet plumbing and leach them from stainless steel. This could lead to premature plumbing failures in the waterjet system.

Dissolved Solids

It is also not good to drink impure water. Many things can indicate impure water. It may have high levels of suspended solids or both. Dissolved Solids refer to the chemical composition of water and what is in solution. Deionized water, for example, has virtually zero dissolved solids.

“Our sweet spot in dissolved solids is between 25 and 50 parts per million (ppm). It is extremely pure water but not deionized. It is very pure water, but it is not super clean,” Petras says.

Under pressure, dissolved substances, particularly calcium and magnesium, can precipitate through the orifice in the nozzle. This causes a poor stream and bad cuts. If you don’t have a water softener or have high calcium content, your waterjet may not work properly. Petras says that if your stream becomes clogged at its nozzle, an ultrasonic cleaner can be used to clean it.”

Petras says that many conditioning systems can be used to clean water and treat dissolved solids. These include reverse osmosis, a water softener, or a calcite filter that treats low pH water. It is important to have a water test done to choose the right water treatment system.

If the pH of the water is low, for example, the acidic qualities of the water can enter and expand the micro-fissures in stainless steel tubing. Although the effect is similar to using deionized tap water, which can lead to a shorter tubing life, the reasons for this are different. This is where a calcite filter can be helpful.

Petras says that suspended solids can be easily controlled with the use of correctly sized filter media in a system.

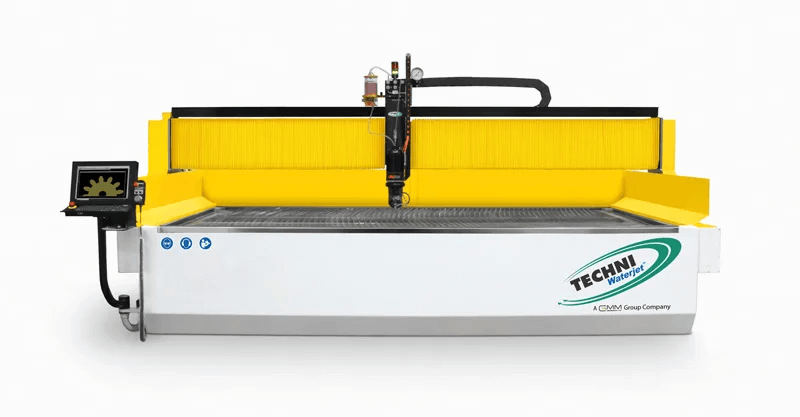

TechniWaterjet

Suspended Solids

Suspended solids can be seen in the water, making it appear dirty. These are usually organic substances such as bacteria, moss, and algae that can cause slime. They can clog filters but can be easily removed with a good filter.

If suspended solids aren’t filtered, they can get in awaterjet pump, seals, and into the nozzle. This can cause a poor working stream at high pressure and shorter pump life.

When you accelerate it to Mach 2, water quality is crucial,” states Bradley Schwartz (Pacific regional manager for Jet Edge). Any particulate matter in water can cause abrasions within the pump at this speed. The waterjet will have trouble if there is a lot of iron or other particulate matter in the water.

Schramm states that Flow recommends the use of a municipal water source, or a well, as a water supply. Untreated water, boiler condensate, and process water are generally not acceptable.

“Ensure that your water-flow rate can produce 1.5 times as much pump-flow rate. He says that if your pump is capable of producing one gallon per minute, your water source must be capable of producing one-and-a-half gallons per hour.

Pre-installation kits from Flow include a water quality test kit. This allows you to determine the hardness, iron, and manganese levels in your water. Flow may recommend water treatment equipment, such as a water softener if these levels exceed the range recommended for the pump type being used. Schramm mentioned that an RO or deionization device is not recommended to remove solids from water because they both remove minerals from water.

Making stable and cool water.

Waterjet companies also point out that water can change throughout the year due to the growth of algae in summer and silt from heavy rainfall.

Heat is another side effect of pump pressure. This heat is a deterrent to long life. Water that is pressurized to at least 40,000 psi will quickly heat up. Pump life can decrease as water temperatures rise.

Schwartz notes that water conditioning for waterjets is usually determined by the environment. We offer a closed-loop water-conditioning system with chillers to maintain a constant temperature if there is a problem with water. This equipment is included in about 60% of the waterjets I sell.

Schwartz also stated that the water quality and temperature of the waterjet “definitely impact the operating cost of the waterjet.” In summer, you will have more silt and a higher water temperature. This can cause problems with filtration and also causes issues with the seal longevity of your pump.

“We prefer filtered water with a TDS level of 50ppm and water temperatures between 60-70 degrees. Schwartz says that when water meets these conditions, seal longevity can be extended up to 1,000 hours for pump seals.

Petras says that temperature is equally important. For pump seal longevity, cold water is better than hot water. Our pumps also come with a 70-degree water specification. This temperature is common to obtain right from the tap. We offer a chiller system for companies who can’t keep this temperature down.

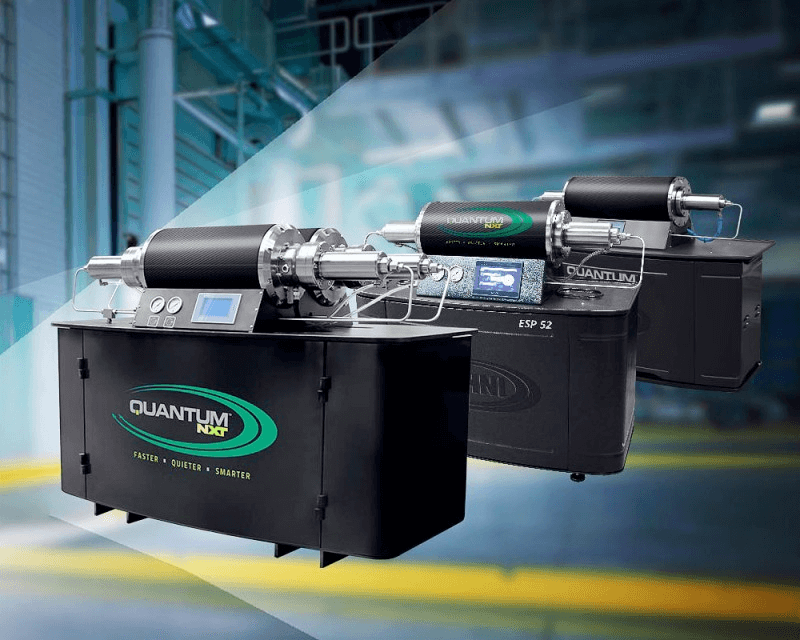

Petras mentioned that his company provides various solutions to improve water quality and prolong component life. We offer RO systems for water purification, as well as a closed-loop filter system for those companies that cannot dump their water down the sink or don’t want to do so for environmental reasons. There are two types of water pH neutralizers. Petras says one is for mild water problems, while the other is designed for more severe water problems.”

Schwartz also mentioned that Jet Edge machines are located in areas that do not have drains. These cases require that water is filtered continuously. The system is three-stage: pre-filtration, then final deionization. This variable deionization system is set at 50 ppm. Anything less than 100ppm is acceptable. However, you might find 500 ppm in different areas of the world. These cases require that your waterjet cutting system has a high filtration level.

Schramm says that Flow offers absolute-rated filters to remove suspended particles from seals, plungers, and orifice assemblies. The filter included with the pump is a 1 and 0.45 micron. If the water supply contains too many solids, these fine filters may clog quickly.

A pre-filter system is recommended for waterjet users to extend the life expectancy of their pump filters. He says that depending on the water quality, a pre-filter system of 50 microns or 5 microns will prolong the life of critical pump filters.

Schramm says that there are two options once the water has been used for cutting. It can be disposed of or reused in a closed-loop system.

“Most customers dump the water because they are cutting neutral materials like aluminum, glass, and steel with natural garnet sand. We recommend that water be disposed of in a weir tank with a filtration system to remove suspended solids and keep them from the sewer.

A closed-loop system will be required if you are cutting lead, beryllium, or any other potentially hazardous material. Schramm says that if you use a closed-loop system, make sure that the water has been chilled and that you have a good filter system before the water is used again by the pump.

Schwartz says, “Whenever I sell waterjet systems, I always give buyers full information about filtration systems because this is very important to many of them. They decide how clean their water supply is.

“Some communities require that water meet a certain level of filtration before it is allowed to go down the drain.” We offer our closed-loop filter system if this is the case.

Schwartz can test the water for customers who purchase a waterjet or have it tested by a local laboratory. Schwartz can also provide a recommendation if a lab tests the water.

Petras concluded that waterjet users could use low-quality water. However, this will not ensure those waterjet components last as long as possible. It is best to do a water quality analysis and then implement the right water conditioning system to suit the waterjet’s needs.