Automotive

In the fast-paced world of automotive engineering, the quest for performance, efficiency, and safety has led to a profound reliance on heat-resistant materials. These specialized materials play a pivotal role in various components of modern vehicles, ensuring the longevity and optimal functioning of critical systems subjected to intense heat and temperature fluctuations.

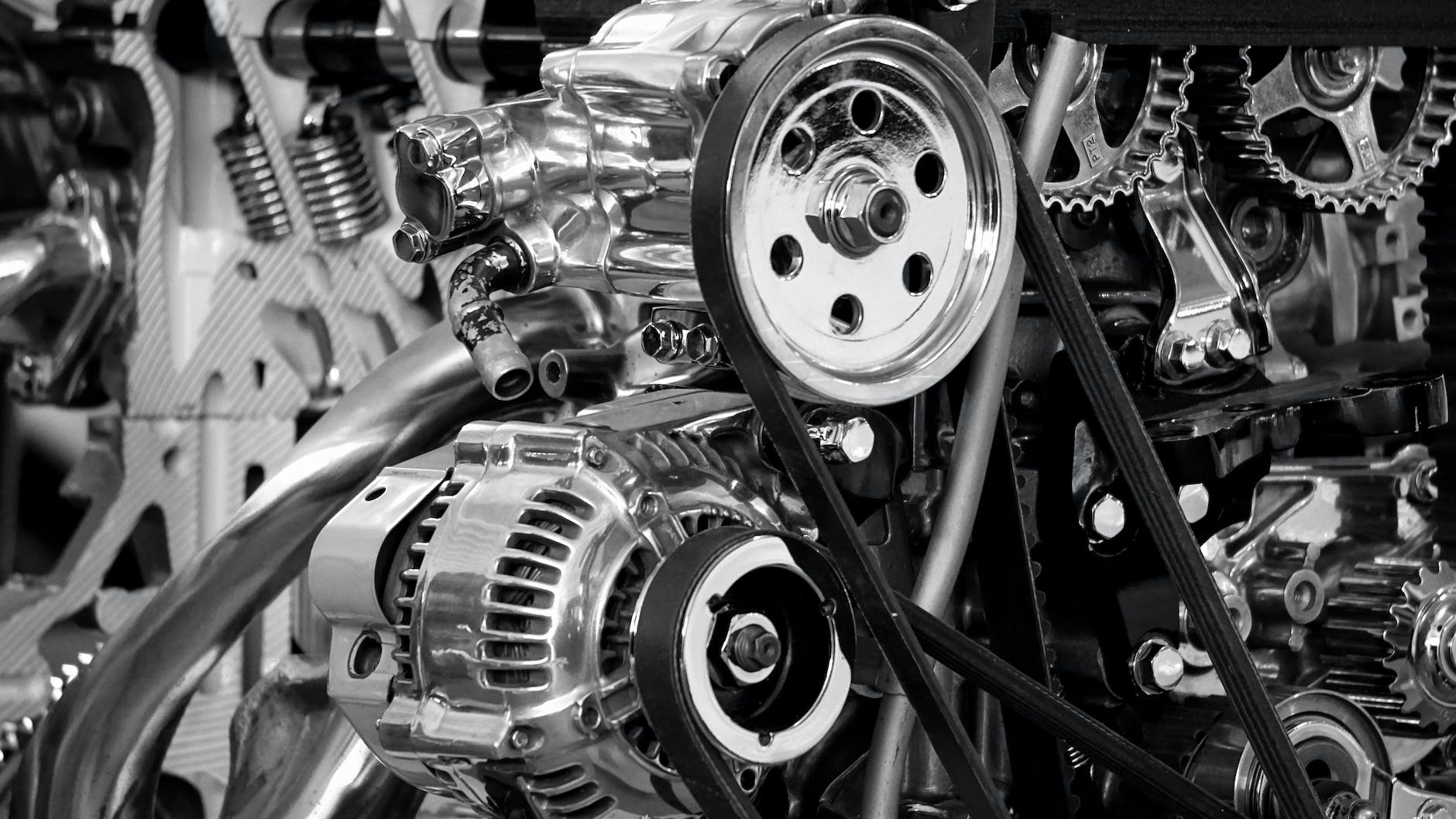

The Engine Bay Challenge

At the heart of every vehicle lies the engine, a complex assembly generating high levels of heat during combustion. To withstand these extreme conditions, automotive engineers incorporate heat-resistant alloys and ceramics into the engine components. From pistons and cylinders to exhaust systems, these materials enable engines to operate efficiently even under intense heat, contributing to overall performance and longevity.

Pushing the Limits

Brake systems experience tremendous heat during operation, especially in high-performance and heavy-duty vehicles. Heat-resistant materials, often reinforced with carbon fibers or ceramic composites, are employed in brake discs and pads to withstand the friction and heat generated during braking. This not only enhances the braking performance but also ensures the longevity of the braking system under demanding conditions.

In the Driver’s Seat

Beyond the engine bay and brake systems, heat-resistant materials also contribute to the comfort and safety of vehicle interiors. Automotive engineers integrate these materials into components such as seat cushions, upholstery, and interior panels to protect against the heat generated by exposure to sunlight and the external environment. This not only enhances the durability of interior components but also ensures a comfortable driving experience for occupants.

Under the Hood Protection

One indispensable element in automotive engineering is heat resistant tape. This versatile material finds applications in various areas under the hood, providing insulation and protection. From securing wiring harnesses to preventing heat damage in sensitive electronic components, heat-resistant tape is a silent hero in maintaining the reliability and functionality of critical systems.

Exhaust Systems

Exhaust systems face the daunting task of managing extremely high temperatures and corrosive gases. Heat-resistant alloys, ceramics, and thermal barrier coatings are employed in exhaust components to withstand the intense heat generated during combustion and efficiently channel exhaust gases. This not only ensures the durability of the exhaust system but also contributes to emissions control and environmental sustainability.

Turbochargers and High-Temperature Resistant Materials

In contemporary engines, turbochargers are commonly used to boost power and efficiency. They operate at elevated temperatures due to air compression. High-temperature resistant materials, specifically heat-resistant alloys and ceramics, are utilized in the manufacturing of turbocharger components. These materials can endure the heat produced by the compression operation, resulting in better engine performance without sacrificing durability.

Electrification and Thermal Management

As the automotive sector moves toward electrification, electric vehicles (EVs) introduce new heat management challenges for battery systems and electric motors. High-temperature resistant materials are crucial for effective thermal management of batteries, ensuring they function within ideal temperature parameters for efficiency and safety. Moreover, these materials aid in the development of electric motors designed to cope with the heat generated during high-performance electric driving.

The Future of Lightweighting

In the pursuit of fuel efficiency and reduced emissions, the automotive industry is increasingly turning to lightweight materials. Heat-resistant composites, combining strength and heat resistance, are gaining prominence in the development of lightweight components. From body panels to structural elements, these materials contribute to the overall reduction of vehicle weight while maintaining the required heat resistance for various applications.

Addressing Environmental Concerns

Sustainability is a growing concern in the automotive industry, leading to the exploration of eco-friendly materials. Heat-resistant materials, designed for durability and recyclability, contribute to the development of sustainable vehicles. From bio-based heat-resistant polymers to recycled heat-resistant alloys, these materials align with the industry’s commitment to reducing the environmental impact of vehicle production and operation.

Conclusion

The crucial role of heat-resistant materials in automotive engineering cannot be overstated. These materials not only enable vehicles to withstand extreme temperatures and challenging conditions but also contribute to advancements in performance, efficiency, and sustainability. As the automotive industry continues to evolve, the innovative use of heat-resistant materials will remain integral to shaping the future of safer, more efficient, and environmentally conscious vehicles.